Pump and Motor Alignment Procedure in Dammam KSA

Pump and Motor Alignment Procedure in Dammam KSA: At ASKA Solution, ensuring the reliability and efficiency of industrial equipment is at the core of what we do. One of the critical maintenance tasks we offer in Dammam, KSA, is Pump and Motor Alignment. Proper alignment is crucial for extending the lifespan of pumps and motors, reducing energy consumption, and preventing costly downtime due to breakdowns. In this blog post, we’ll walk through the Pump and Motor Alignment procedure, explain why it matters, and how our team at ASKA Solution ensures your equipment is running at peak performance.

Table of contents

What is Pump and Motor Alignment?

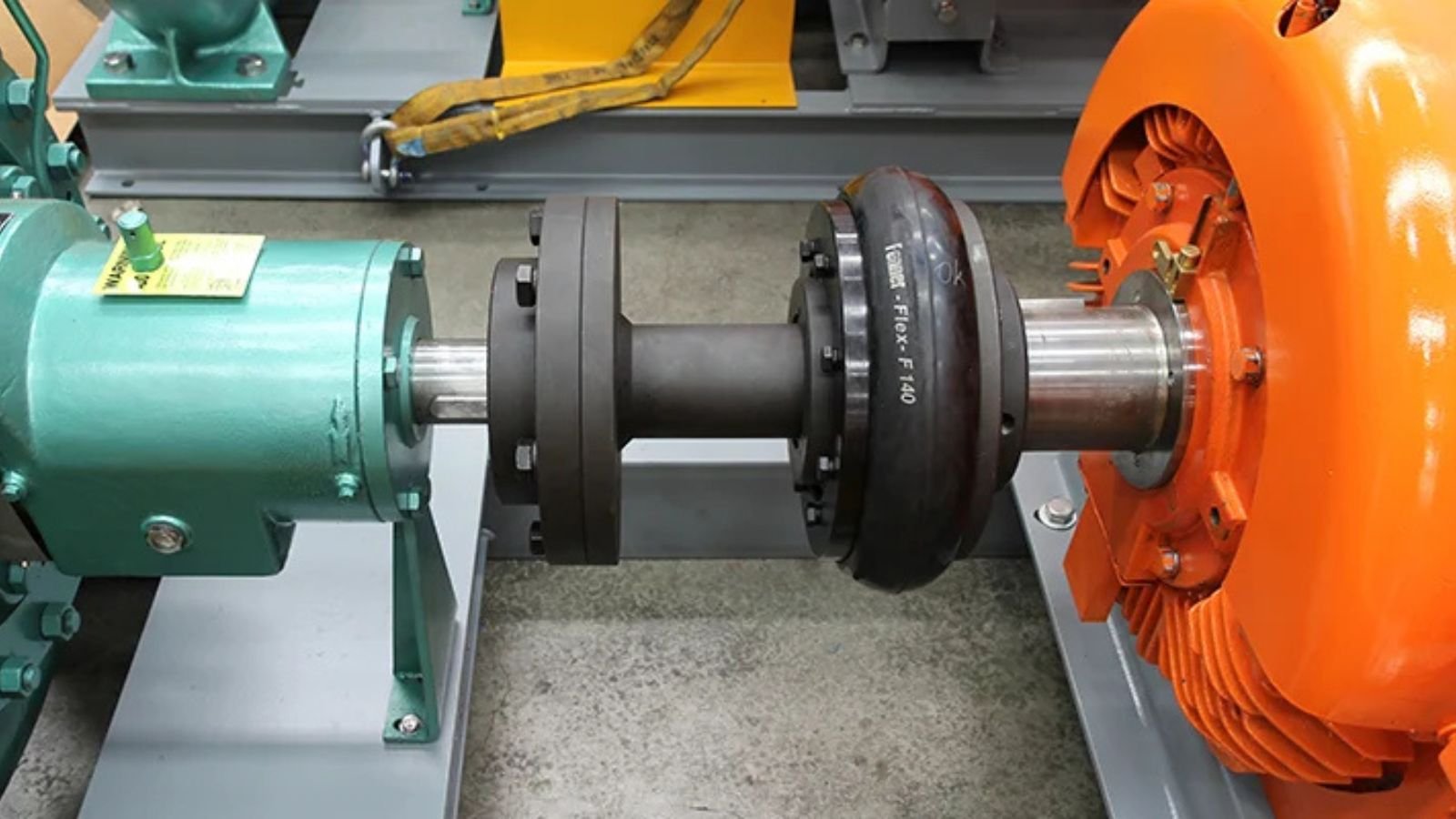

Pump and motor alignment is the process of aligning the rotating shafts of the pump and motor to ensure they are positioned correctly with each other. Misalignment can cause excessive vibration, heat, and wear, leading to equipment failure. There are two main types of misalignment:

- Angular misalignment – When the shafts of the motor and pump are not aligned at the same angle.

- Parallel misalignment – When the shafts are not positioned in parallel, but their angles may still match.

Read Also: How To Manage A Large Commercial Plumbing in Saudi Arabia

Proper alignment ensures that the force from the motor is transmitted efficiently to the pump, minimizing wear and increasing efficiency.

Why is Alignment Important?

- Reduced Wear and Tear: Proper alignment minimizes friction between parts, reducing wear and tear on components such as bearings, seals, and couplings.

- Energy Efficiency: A well-aligned system consumes less energy as the motor doesn’t have to work as hard to power the pump.

- Extended Equipment Life: Regular alignment maintenance extends the life of the pump, motor, and associated equipment, resulting in fewer breakdowns and costly repairs.

- Minimized Downtime: Misalignment can cause premature failure, leading to unplanned downtime. Regular alignment helps avoid unexpected breakdowns.

- Safety: Misaligned pumps and motors can generate excess heat and noise, which can be a safety hazard in an industrial environment.

ASKA Solution’s Pump and Motor Alignment Procedure

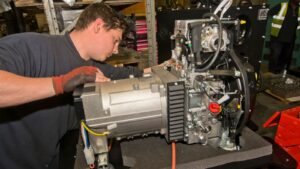

At ASKA Solution, we use cutting-edge technology and highly trained technicians to perform precise alignments. Our step-by-step alignment procedure includes:

1. Initial Inspection

Before any alignment work, our team inspects the pump and motor for any visible damage, such as worn bearings, loose bolts, or cracked housings. We also ensure the foundation of the equipment is stable and free from vibrations.

2. Checking Soft Foot Condition

Soft foot refers to an uneven or imbalanced condition in which one or more feet of the motor or pump do not rest firmly on the base. We check for soft foot using precision tools to ensure the machine’s foundation is solid.

3. Measuring Misalignment

Our technicians use laser alignment tools to measure both angular and parallel misalignment. These tools provide real-time data, ensuring accuracy within thousandths of an inch.

4. Correction of Misalignment

Once the degree of misalignment is known, we make the necessary adjustments by either shimming or moving the motor or pump into the correct position. Laser tools provide feedback to ensure the shafts are perfectly aligned.

5. Rechecking Alignment

After making the corrections, we recheck the alignment to verify that everything is in line. This ensures the alignment meets industry standards and that the equipment will operate smoothly.

6. Documentation and Reporting

At the end of the alignment process, we provide a detailed report to the client, which includes the initial misalignment readings, the corrective actions taken, and the final alignment readings. This helps in tracking the performance and maintenance history of the equipment.

Why Choose ASKA Solution for Your Pump and Motor Alignment in Dammam?

ASKA Solution is a leading provider of industrial services in Dammam, KSA, specializing in pump and motor alignment. Here’s why businesses trust us:

- Expert Technicians: Our team consists of experienced professionals with extensive knowledge in pump and motor alignment.

- State-of-the-Art Technology: We use advanced laser alignment tools that ensure precision and accuracy.

- Comprehensive Service: From initial inspection to post-alignment reporting, we offer a thorough and reliable service.

- Customized Solutions: We tailor our services to meet the specific needs of your industrial setup, ensuring your equipment runs at peak efficiency.

- Industry Standards: We adhere to international standards and best practices, ensuring that your equipment complies with all safety and operational guidelines.

Preventive Maintenance: Keep Your Equipment Running Smoothly

In addition to alignment, ASKA Solution offers a wide range of preventive maintenance services to help you get the most out of your equipment. Regular checks and maintenance not only ensure optimal performance but also save you money by preventing costly breakdowns.

Contact ASKA Solution for Pump and Motor Alignment Services

If you’re looking for professional pump and motor alignment services in Dammam, Saudi Arabia, look no further than ASKA Solution. Our experts are ready to help you maintain your equipment’s performance, extend its lifespan, and reduce energy costs.

Contact us today to schedule an inspection or learn more about our comprehensive industrial services.

Add comment

You must be logged in to post a comment.